Noisy Pumps!

These pumps have a rotary

piston action so are inherently quite noisy and subject to

vibration. If mounted incorrectly the vibration can be

transmitted through the fabric of the house and create an

unacceptable background sound, especially in full sun

conditions.

If this over-revving in

bright sun is a new problem it may indicate that the

valves are failing as this reduces the resistance to

revolving as less water will be being pumped, in which

case you may also be able to see the panel temperatures

rising to higher levels than previously due to the

decreased transfer of a slow flow rate. If so then it

might be time to get the pump checked out, which we are

happy to assist you with and you will see notes on that on

this page.

The pumps are designed to

increase speed with the strength of the sun hitting the PV

panel, with the logic that therefore the water panel

should also be creating more heat which needs transferring

faster. This is good, but the pumps can get a bit

over-enthusiastic in direct sun, with a noticable increase

in sound level.

......Recommended Pump

Mounting Method to avoid sound transmittance.

If you have checked the

mounting method is not allowing vibration to conduct to

the fabric and are still bothered by the noise then I have

found a method of capping the peak voltage coming from the

panel to place a cap on the motor's top speed, as this is

when most people notice the noise.

In this maximum power state

the flow rate is probably faster than is really required

anyway.

Speed

Control ....... Speed

Control .......

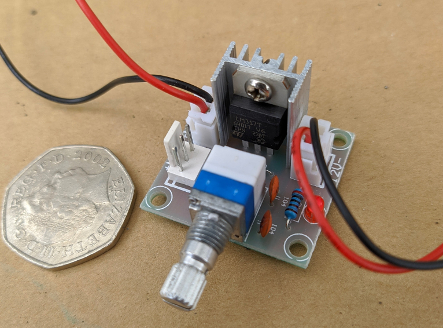

These circuits are available

for around £5 or less on eBay, search for "LM317 Speed

Control" or try this

link: They are very easy to fit, feed the pump power

in to one side and out to the pump on the other side.

The peak voltage can then be

set by ear on a sunny day. From fully clockwise, Turn the

power down until you get an acceptable noise level.

Keep an eye on the water panel temperature to check that the

new flow rate is still enough to shift the heat away to your

tank without the panel boiling.

SolarTwin

Controllers

Newer SolarTwin systems

included a Differential Controller, powered by the PV

panel. Its function is to ensure the pump only runs when

there is heat available in the panel. This controller

delivers improved efficiency versus the early system

whereby the pump runs whenever there is enough light

hitting the PV, irrespective of heat being available.

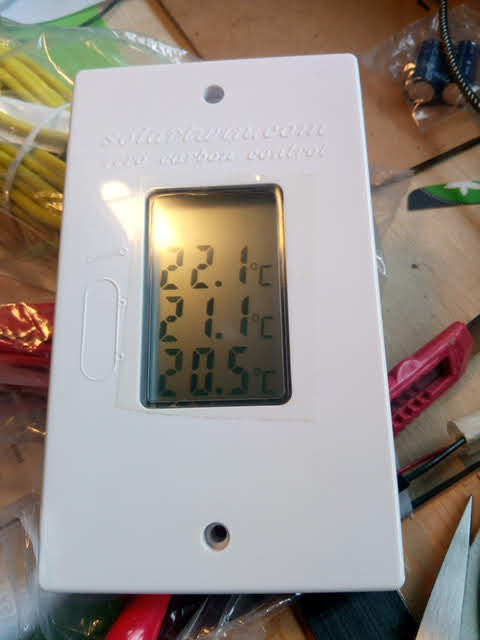

In this photo the arrows

pointing down at the panel icon at top left of display

indicate the pump has been switched on to capture heat.

The temperature displayed is at the tank top, indicating

the stored water temperature.

We have seen several of

these controllers breaking down after a few years,

usually due to the failure of two key components which

prevents the controller storing sufficient power to run

itself. If you have a faulty controller then contact us

to explore whether it may be repaired.

This Loss of Display fault

is due to a couple of the components on the circuit

board breaking down. Contact us if you'd like us to fix

this, it will require removing the front cover and

sending it to us. Meanwhile the pump can be connected

directly to the PV panel for the few days it will be

away and the pump will run normally during that time,

that is how the original systems were installed before

the controllers were added. This Controller fix is

inexpensive at £23 inc UK postage.

The panel temperature

probes seem to suffer from inaccuracy in some

installations. These are a PT1000 type sensor on a very

long length of co-ax cable so I wonder if fitting a

small capacitor (around 0.1uF) across the two wires as

they enter the controller casing would help avoid

erratic reads. I'd be pleased to hear from anybody who

could try this fix.

Other common faults

include a failing panel temperature probe. Spare sensors

are available on request but they are fitted into the

rear of the panel so replacement involves climbing on

the roof to lift the panel in order to gain access to

the cable entry point.

New controllers are hard

to find, though I do currently some in stock at

£110 each (including three sensors and cabling)

if yours cannot be fixed. They aren't listed in my shop

so email me for availability

The default display on

these units shows only the temperature of the hot water

tank, measured at the top. There is an alternative display

mode which is useful for setting a system up, whereby all

three probe temperatures are shown on the same screen.

Accessing this is supposed to be by opening the controller

case and pressing UP DOWN and SET buttons together for 30

seconds.

We found this did not

work on our sample, so try the following sequence to

change the display:

1/ Hold down SET and then

press RESET briefly. The display shows "EEP" with "000"

beneath it.

2/ Now press SET once more.

The three temps will show,

the upper one is the panel temp, middle is the tank top

temp and the third is the tank base measurement. On the

unit I tested this also switched the pump on, irrespective

of temperature delta, so is only useful for de-bugging

sensors, not for constant display use.

Return to the default

display by pressing RESET.

I have learned some useful

things about this controller - It doesn't seem to like

being asked to switch when supply voltage is below 7.5V,

although it continues to read and display ok at this low

voltage. A faulty pump with high current draw might cause

the input voltage to drop so try disconnecting one pump

wire to see if that corrects a controller error. The

controller passes whatever the input Voltage is on to the

pump, hence the variable speed.

Similarly, the two

supercapacitors often fail, try unplugging them completely

in case they are pulling the voltage down with a short

circuit. These are replaceable if failed. Finding a

similarly rated part with the same physical dimensions may

prove very hard, in which case the new supercapacitors

might have to be mounted externally but they will work in

that position if necessary.

The controller compares the

panel temp with the tank top temp to decide when to run

the pump (not the tank base as with every other type of

controller!) There is a time delay of 30 seconds or more

before the unit switches the pump after detecting the heat

delta.

The panel probe is a type

PT1000. At room temperature it will have a resistance of

circa 1068 Ohms. The two tank sensors are NTC10K and have

a room temp resistance of around 13k Ohms. If you are

getting implausible readings then checking that the

resistances across the disconnected wires of the sensor is

a good idea. The resistances at different temps can be

found by googling for a sensor chart for that type of

sensor.

On the display : the inward

pointing arrows are shown when the controller has passed

power to the pump. If the tank top exceeds 60 degC and the

panel is less than that temp then the pump is switched on

to export heat and cool the tank. Outward arrows show when

in this state.

Possibly Useful Solartwin reference

documents

Original

Installation Instructions to installers

Solartwin

User Guide

Leaking

Collector Panels

Here in 2023 I am hearing of more and more people reporting

their panel has begun leaking and dripping on to the

roof. So clearly the silicone tubing inside the panel

has a finite life span is starting to fail.

If this happens to you then it isn't a quick fix but here is

some encouraging news from a customer that you may find

helpful:

"

When I spoke to someone in Genfit they said it had

come to their notice that the silicone tubing was

breaking down in older panels. They would have

supplied a new panel for £1000 (plus carriage) but I

thought it would be worth giving it a go so I took

the panel down (first mistake – forgot about the

temperature sensor so broke the cable!). I

tried drilling the rivets but too slow so took a

small angle grinder and took the top of each one

(much quicker but approx. 260 rivets) and then with

a block of wood underneath the rivet, punched out

each of the rivets. I replaced the tubing and

riveted it all back together. Some of the

rivets pulled through but otherwise still held and I

touched up some of the black paint as appropriate.

I

got the sensor and tubing from DiscreteHeat;

Yellow Sensor £18.95, 24m of 16mm Silicone (food

grade) £120 , shipping £15 all plus VAT so cost me

£185 plus a box of rivets out of Screwfix and now

thanks to your help it is running!

Took

some time but I think worth it all and especially

because the design is so simple.

Hope

this might help someone else.

David

"

If

you decide to tackle this rebuild job then contact me

as I should be able to source the tubing (or sensor!)

at a good price, making it even more viable.

Obviously not a simple task but quite

manageable. I might even have a repaired panel

available as an exchange

Here is some information on how to fix that leak I hope it is helpful to you in deciding what action to take. The repair project took me a little over a day to complete.

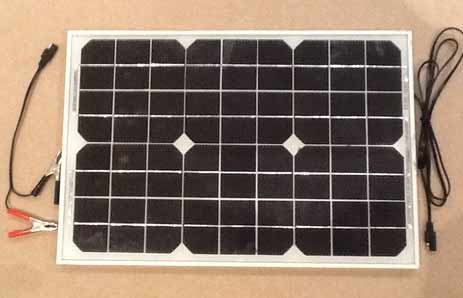

PV Panels and System Checks

The PV panels used are all 5Watt

and there isn't much to go

wrong with a PV panel, but if you have no power output

then check the wiring carefully before seeking a new

panel, it is much more likely to be a wiring fault than

a panel failure. I have some spare panels if you need

one.

Slightly confusingly,

SolarTwin used two different specs of 5Watt PV,

nominally 6V and 12V. A quick check of the voltage

across the wires "Open Circuit" ( i.e. disconnected from

the controller and pump) will confirm which you

have. If you measure over 18V then you have the

12V panel, 9V indicates the 6V panel. This is

significant when making the checks described

below. The spec of the PV is shown on the rear of

the panel if you remove it from its mounting. Slightly confusingly,

SolarTwin used two different specs of 5Watt PV,

nominally 6V and 12V. A quick check of the voltage

across the wires "Open Circuit" ( i.e. disconnected from

the controller and pump) will confirm which you

have. If you measure over 18V then you have the

12V panel, 9V indicates the 6V panel. This is

significant when making the checks described

below. The spec of the PV is shown on the rear of

the panel if you remove it from its mounting.

Shown Left is an example of the

Spec Label on a 6V PV panel

If you suspect your PV panel may be

faulty then there are a couple of tests you can carry out.

You will need a digital voltmeter, there are plenty of

suitable models on eBay for little over £5.

STEP 1. On a bright sunny day with the

panel facing the sun - Disconnect one of the wires that

lead from the PV panel to the controller so that no

current can be being drawn by the pump etc.

STEP 2. Switch your voltmeter to the

10Amp setting. (You may need to locate one probe lead to

the 10A socket on the meter for this function)

STEP 3. Place the meter leads on each PV

wire to measure the PV output in a 'dead short'. For

the 12V panel I would expect a reading of 0.25Amp or more

in strong sun. If you are getting much less 0.2Amps then

consider looking for a wiring breakdown before concluding

that the panel is broken. Similarly the 6V panel

should give 0.4Amps or more.

If the problem you identified was the

pump running too slowly or not pumping properly then

reconnect the PV to the controller and remove one lead

from the pump. Now bridge the gap from pump lead to the

controller terminal with the meter probes, so that you are

now measuring the current being drawn by the pump.

A healthy pump will draw between 0.2 and 0.3 Amps to give a

good flow rate. Now try squeezing first the inlet pipe then

the outlet pipe to restrict the flow. You should hear the

pumps note change under the increased flow resistance and

the current will increase on your meter. If the pump note

does not change then the pump may need servicing, please

see my service offer above.

Advanced

Problems and Solutions - Blocked Panel

Circulation

If your pump tests OK but you are still not getting any

hot water circulation then it is time for some more tests

to identify the cause. I will assume you have checked and

rechecked that the pump is primed properly as a build up

of air in the pump is still the most likely cause.

I have seen a few cases recently where a blockage is

preventing circulation. If your pump starts up OK but

stops after a minute or less then it may be trying to push

water against a solid obstruction. A pump with perfect

valves will stop under this resistance, others may still

revolve slowly as the pressure relief valve allows the

pressure to discharge slightly.

Solartwin systems in hard water areas should

have had a water softener fitted but this was not always

the case. This prevents a limescale build up in the panel

and pipework. If you can feel pressure from the pump on

the outlet pipe next to the pump but the temperature of

the panel is very hot then you might suspect there is a

blockage somewhere in the circuit.

This may be confirmed by attaching a garden hose to the

outlet pipe to see if mains water pressure can push water

through the circuit. With just a trickle of mains flow

applied you may feel the hose being pushed off as the

pressure builds, whereas a healthy system will allow that

flow and the pressure remains low.

So you have concluded there is a blockage? Familiarise

yourself with the above circuit diagram, then here is the

order I would tackle this:

1/ Check the pipes for any kinks. With the pump running,

Cut or Remove the pipe leading from the Collector Panel at

the point it connects to the top of the water tank

(probably on the 1 inch pipe above the tank). If you've

enough slack then bending the white pipe over once and

taping the bend by the cut will seal it. Afterwards you

can discard the short offcut and refit the longer pipe to

avoid having an extra joint. Use a bucket to catch water

from the white pipe..

2/ Is the pump pushing water out the soft white hose? If

a steady flow is observed there is no blockage. If not

then the most likely site for a blockage is in this pipe.

This is because the panel itself contains pipe that is a

much larger bore so any blockage will pass through until

it hits the narrower white return pipe (6mm ID) .

3/ If it is blocked then try back flushing this pipe with

a hose, after having removed the pipe at the point it

leaves the pump. This allows the pressure to blow off

whereas the pump would block it.

People have reported success using a good bike pump and

Schrader valve blowing air to shift the obstruction (this

avoids spillage issues in your loft if it works. As the

pipe is soft silicone it will inflate slightly under air

pressure and that may be enough to shift the blockage,

albeit back into the panel. If it blocks again try blowing

through in the direction of flow. Of course, if you can

access the pipes on the roof then it would be best to

remove them from the panel so any blockage is blown out,

but most prefer to work inside for good safety reasons!

If you have hard water and can see that limescale is a

likely cause then filling the pipe system (on a dull day!)

with descaler or vinegar for 24 hours or more would be a

good idea, but this can only be done once the blockage is

moved. I am guessing that it will take 3 or 4 litres to

fill the system from between the pump outlet to the point

the pipe joins the hot tank, so both pipes need to be

disconnected during that soak exercise.

If this proves useful then please share your experience

with me for the benefit of others in the future.

go

to HOMEPAGE or here

to go to

SOLAR FAQ page

Q&A or here for

INSTALLATION

GUIDE

|